Fast and Correct Mortises – FineWoodworking

Synopsis: There are many methods to chop mortises, however in Bob Van Dyke’s store and within the courses he teaches, a plunge router with a router field is the go-to methodology. With this straightforward course of, a plunge router with a fence cuts the mortise whereas using on prime of a three-sided field that holds the inventory. Right here he reveals you tips on how to make the field and tips on how to use it.

I’ve minimize extra mortises utilizing a plunge router and a router field than with every other methodology, together with a hollowchisel mortiser. Consider all of the methods there are to chop mortises in a desk leg. They are often chopped by hand with a mortising chisel and a mallet, or you may drill out the mortise and pare to your structure traces. A hollow-chisel mortiser works nice, however mortises are the one factor it may do. A router desk with a fence is definitely a viable methodology, or you may at all times use educated termites. A plunge router with a router field is arms down one of many best and most correct strategies that I’ve used. In my faculty, I determine we’ve revamped 8,000 mortises this fashion. And the identical router may also make moldings, roundovers, curves, and a lot extra. Strive doing a Roman ogee with a hollow-chisel mortiser!

Making the field

The router field is a fundamental affair. For the bottom, glue and screw two items of three ⁄ 4-in. plywood collectively, then straighten one edge and rip the opposite edge parallel. The edges are plywood screwed to the bottom. The highest edges of each side have to be the identical peak above the floor of the bottom, or your mortises gained’t be sq. to the face of the workpiece.

I make the field massive sufficient to accommodate a spread of different-size legs. The peak of the edges is 2-1 ⁄ 8 in. above the bottom (1 ⁄ 8 in. larger than the largest leg I’d do on this jig) and the width between the edges is round 2-5 ⁄ 8 in., vast sufficient to suit a 1-1 ⁄ 2-in.-square leg, plus a 7 ⁄ 8-in. spacer and some wedges to carry it. Use a thinner spacer when mortising larger legs. The precise size of the field isn’t essential.

The bit

I want a strong carbide spiral bit particularly designed for plunging. The spiral flutes simply eject the chips. A straight bit additionally works, however the spiral simply works higher. There are plenty of good spiral bits on the market, however I take advantage of the Whiteside RU2100.

Constructing the router field

Development doesn’t get a lot simpler than this: 4 items of plywood glued, clamped, and screwed collectively.

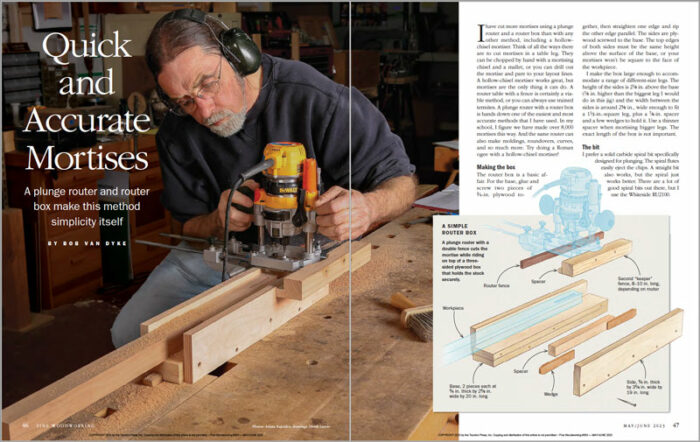

Utilizing the field

When you construct your field, lay out the mortise on a take a look at, or “setup” leg the identical width and thickness as the actual leg and lengthy sufficient to suit securely within the field (12 in. is sufficient). Put your setup piece into the field towards the proper aspect. Use two wedges on the left aspect to carry it in place. If you happen to set the leg on the left aspect with the wedges on the proper and the fence on the proper, the inconsistent strain on the wedge will lead to an inconsistent mortise. Setting the workpiece on the proper, the fence on the proper, and the wedges on the left negates this downside; the space between the fence and the mortise won’t ever change.

Most legs get two mortises—one in every of two adjoining faces— and the fence setting is normally the identical for each. After you’ve set the fence and minimize the primary mortise, you chop the second by merely turning the leg end-for-end. As a result of the piece have to be turned, I don’t trouble setting stops to regulate the size of mortises.

—Contributing editor Bob Van Dyke runs the Connecticut Valley College of Woodworking.

Photographs: Anissa Kapsales.

Drawings: Derek Lavoie.

For the complete article, obtain the PDF under:

From Fantastic Woodworking #303

Join eletters in the present day and get the most recent methods and how-to from Fantastic Woodworking, plus particular presents.

View FREE Mission

if you enter your electronic mail handle under.