Tune up an all-purpose hatchet right into a carving axe

As a spoon carving instructor, it hasn’t been simple to seek out an inexpensive however good carving axe, not less than right here in Spain.

Once I was beginning out, I used to be fortunate to have the ability to get a Gransförs Massive Carving Axe, (which I later regretted, and I’ll let you know why in a bit) however most of my college students want to carve spoons as a passion and don’t actually wish to make investments rather a lot.

The excellent news is you don’t want an costly carving axe; you possibly can tune up an all-purpose hatchet into a superbly good carving axe to get began.

It actually all comes down to 3 staple items: dimension, weight, and edge geometry.

Weight

A carving axe must be mild sufficient so we will carve for some time and never get fatigued, additionally heavy sufficient so the chopping motion is environment friendly because of weight of the pinnacle however nonetheless permits us to have good purpose.

For me, the candy spot is round 650 grams (1.5 lb.). That’s why I regretted shopping for the Gransförs, which was means too heavy and ended up injuring my wrist. I do know loads of carvers, larger than me, for whom the Gransförs is ideal. In any case, Gransförs is from Sweden and I’m a tiny Colombian who’s most likely the identical top as a mean 12-year outdated Swede.

Dimension

Dimension sensible, most all-purpose hatchets you discover in {hardware} or residence enchancment shops are acceptable for carving, with deal with lengths round 30-40cm and heads between 400-800 grams.

Once we discover one which feels snug and the right weight for us, we simply must grind the right edge geometry for carving.

Edge geometry

Most hatchets include a bullet-shaped edge meant for splitting firewood and chopping that doesn’t require a lot precision. For carving, we’d like extensive bevels, ideally flat so we will slide on the wooden and really have interaction the sting.

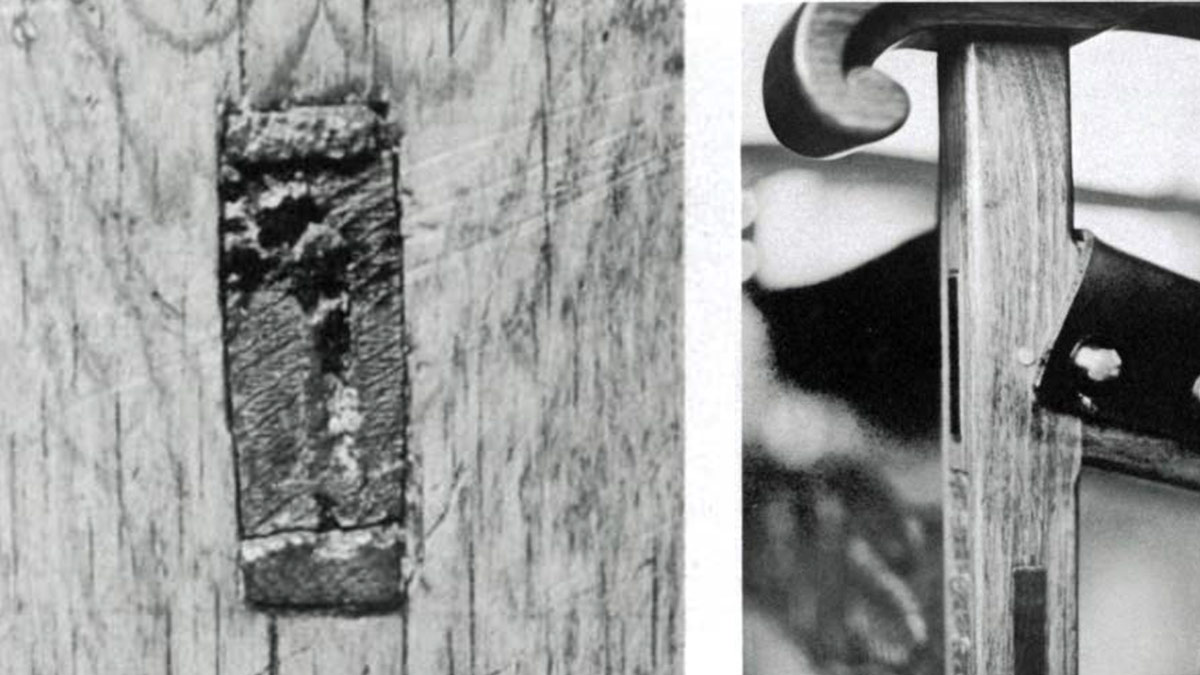

The very first thing we have to do is grind off the convexity and set two symmetrical bevels.

Widening the bevels

The broader the bevels, the better will probably be to interact the sting in a really managed means, which is nice for along-the-grain motion however not a lot for chopping as a result of the sting can be too fragile. So we have to discover a steadiness which can rely additionally on the thickness of the axe head.

For the kind of axe I’m working with, bevels of 9-10mm (round ⅜ in.) work greatest.

I take advantage of a everlasting marker to attract the width of the bevel, which can assist set up the right angle on the grinding wheel by aiming to the center.

I take advantage of a quick grinding wheel first to take away metal as quick as potential after which transfer on to a slower, water-cooled sharpening system which additionally permits extra management of the angle to get completely even hollow-ground bevels.

It’s vital to really feel a burr all alongside the sting after we end grinding both sides.

Submitting down

Now we will transfer on to making a flat bevel utilizing diamond information or common sanding paper on a scrap wooden block. It’s vital to make use of a development of grits that enables us to erase the tracks from the earlier one till we get a refined floor.

Being very cautious, place the file on the bevel, ensuring it’s registering the perimeters of the concavity, and slide the file alongside the sting till there’s seen scratch sample of the identical width and there’s a slight burr on the opposite facet. Repeat on both sides utilizing all of the grits.

The hollow-ground edge can really feel very bitey however as we use the axe and proceed to sharpen it, the bevels will grow to be flat and this may change the best way the sting engages the wooden. You’ll be able to regulate this to your liking by sharpening fully hole with a skinny micro bevel or going for the complete flat bevel.

We’ve now a superbly good carving axe to get began with. As an additional step, we will re-shape the deal with to make it look higher. I like stripping off the shiny end utilizing a card scraper and creating small sides for a nicer grip. Apply some pure oil for cover and luxuriate in!

Join eletters immediately and get the most recent methods and how-to from Fantastic Woodworking, plus particular provides.